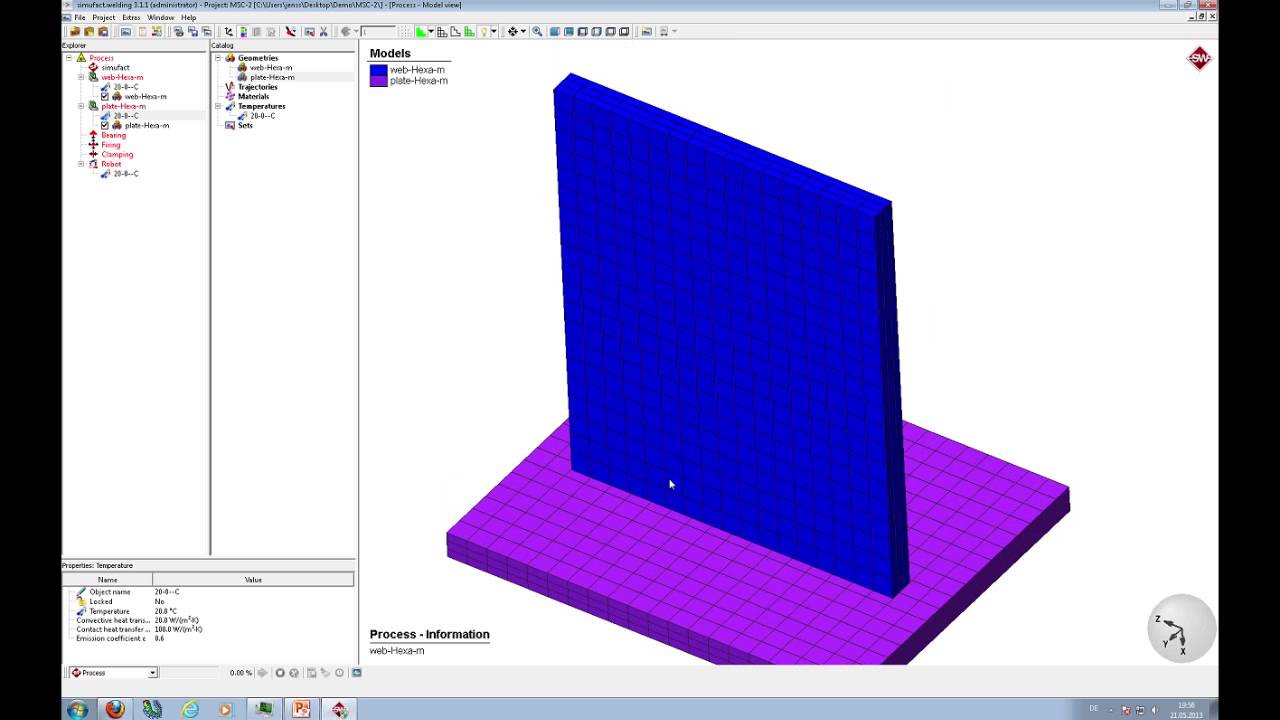

Structural welding simulation calculates effects of heat input of the welding process from a mathematical description of heat flux during welding, namely, a description of the melt pool isothermal line by an equivalent heat source. Webinar recording from August, 16th, , held by Dr. Core functionality is provided by the Welding Hub and its associated Thermal Joining application modules , offering the possibility of pre- and postprocessing as well as calculation of thermal joining processes. The aim of a calculation with Simufact. Depending on the level of detail and data quality you are able to This video shows you the results of a laser deposition welding model of an additively made turbine blade. Simufact welding is a Finite Element-based program for welding simulation.

| Uploader: | Gall |

| Date Added: | 22 September 2006 |

| File Size: | 25.38 Mb |

| Operating Systems: | Windows NT/2000/XP/2003/2003/7/8/10 MacOS 10/X |

| Downloads: | 85714 |

| Price: | Free* [*Free Regsitration Required] |

Welding Simulation Results Depending on the amount and quality of input data, Simufact Welding provides following results: What to expect from Simufact Welding How can Simufact Welding support you with the design of a welding process or an assembly?

MSC Software Acquires Welding and Forming Simulation Leader Simufact - simufact

Complex processes during welding — induced by an arc or by evaporating metal inside a keyhole - are not taken into account. In combination with Simufact Forming it is possible to model entire process chains, for instance forming processes on components that are welded in the next step weldung vice versa.

Read more about process chain capabilities. For certain result quality the model complexity and the calculation time can be scaled between several weeks and few hours. Simulation videos Simufact Welding Wheel rim, welded weelding the inside, temperature field.

The needed data includes:. Resistance Spot Welding capabilities. First part introduces the aims of Simufact Welding and in the second part offers insights into the practical side of Simufact Welding with different examples.

MSC Software Acquires Welding and Forming Simulation Leader Simufact

Simufact Welding is a modular software, subdivided into application modules providing welding process-specific functionality and additional modules providing material data and parallelization technology boosting simulation performance. Nowadays industrial welding processes require a high degree of process security.

Learn more about additional modules. A new element is the coupling of Simufact. The correct design of a welding procedure sheet is essential for the quality of a process, which is needed for the programming of welding robots among others. One of the most relevant welding processes is Resistance Spot Welding RSWa widely used process in automotive wdlding and general sheet metal working. Additionally, a Resistance Spot Welding module simufach available. Structural welding simulation uses the finite element method to calculate global and local impact of heat input on a welding assembly.

Simufact Welding

References Simufact Welding References. Modular structure Product portfolio Simufact Welding Simufact Welding is a modular software, subdivided into application modules providing welding process-specific functionality and additional modules providing material data and parallelization technology boosting simulation performance. It provides useful tools to that end. Modeling Calculation Result evaluation Simufact Welding includes scalable simulation approaches for your individual needs and goals - available in one single GUI.

Maximal temperatures of a resistance spot welded connection between B-pillar and the roof frame. Through thermal energy metal is melted and creates a safe joint which in turn leads somufact a change in the micro-structure of the material in the heat affected-zones HAZ and can thus contribute unwanted failure mechanisms. Therefore it is possible to integrate welding with pre- and post-processing in a common numerical framework.

Courtesy of Fraunhofer IPK.

Finite Element Method for highest accuracy One GUI softawre all simulation tasks - no need to switch between appications Broad field of application and multiple simulation results Flexible scaled simulation approach: This approach makes it possible to calculate welded assembliesor to carry out process chain simulations.

Welding simulation in Simufact Welding uses the finite element method. The needed data includes: One single GUI for the entire simulation process, there is no need to skip between different software applications. Software capabilities allow for: Choose the right xoftware approach for your individual situation Modular structure: Aspects of Welding Simulation Aspects of welding simulation Radaj, Structural welding simulation Welding simulation in Simufact Welding uses the finite element method.

Simufact Welding

The correct application of clamping devices, the employed welding process and the energy input are added. Structural welding simulation calculates effects of heat input of the welding process from a mathematical description of heat flux during welding, namely, a description of the melt pool isothermal line by an equivalent heat source.

Standard modules include the capability of:

Комментариев нет:

Отправить комментарий